SanlengBio is located in Guilin,the landscape of the world.

Since 1993, we have been committed to identification, research, development, production, and promotion of natural botanical extract, intermediates, APIs, and high-purity active ingredients for over 30 years.

In 2019, NATCO joint venture was founded in the United States to further expand international business.

We have two GMP manufacturing bases, Lingchuan manufacturing base and Suqiao manufacturing base, which are capable of processing and handling over 100,000 tons of monk fruits every year.

With an independent technology innovation and R&D center,we collaborate with top universities and scientific research institutions such as Shanghai Institute of Materia Medica, SouthChina University of Technology, Beijing University of Chinese Medicine, Guilin University of Technology and Guangxi Academy of Agriculture Science.

In 2024 we officially took over a demonstration base from local government. The demonstration base covers over 600 Mu (98.84 acres), with a total investment of over US $5.5 million. An off-season monk fruit cultivation demonstration area, intelligent glass greenhouse for monk fruit seedling, virus free monk fruit seedling lab,selenium-enriched monk fruit planting demonstration base, digital & automatic spray pump and irrigation facilities are built in the demonstration base to comprehensively increase added value and market competitiveness of monk fruit and guarantee that monk fruit industry runs in a sustainable and stabilizing way.

With a well-developed quality management system,we are traceable and effectively control the entire supply chain process from seedling to final product.We carry out all of our operations under the GMP guidelines.Our products have already been certified with USDA Organic with Canadian Equivalency, EU Organic, Kosher, Halal, Haccp, ISO22000, ISO9001, FSMA, BRC, FEMA GRAS, and Non-GMO.

SanLengBio’s founder Mr.Mao, who graduated from CAU (China Agricultural University) and majored in plant nutrition science, got experienced R&D staff together and created independent R&D center. With technical accumulation for years, cooperating with leading domestic scientific research institutions like Guangxi Academy of Agricultural Science, Chinese Academy of Science, Beijing Laboratory Center, SanLengBio has already owned a professional and powerful R&D team.

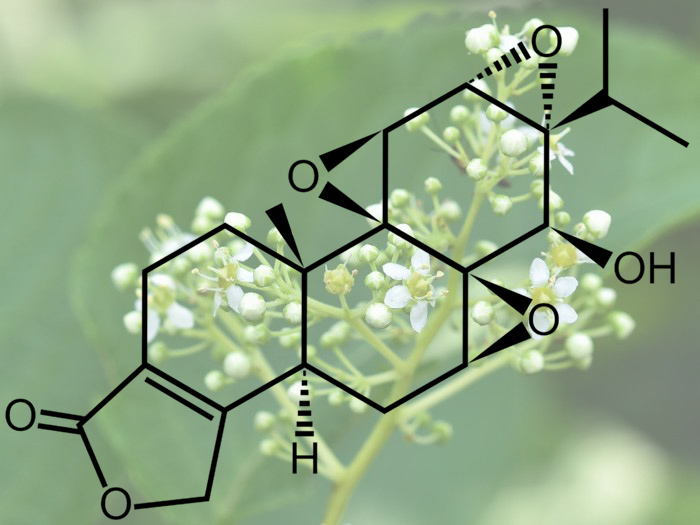

So far SanLengBio has mastered a serious of core techniques including APIs selection, natural ingredients extraction and purification , as well as macromolecule separation in the botanical compounds, which formed an independent intellectual properties system and attained many national invention patents, such as manufacturing technique extracting 98% quercetin from overground part of Ilex pubescens (Patent No.: ZL201010550720.7), recombination countercurrent method extracting Ursolic Acid from persimmon leaves (Patent No.: ZL200910113982.4), a membrane separation technique manufacturing high purity triptolide (Patent No.: 201710115897).

SanLengBio has been at the forefront in terms of production capability.

With two GMP manufacturing bases, the one is Lingchuan manufacturing base with 13,000 ㎡covering area and over 5000 tons raw material processing capability.

Another is Suqiao manufacturing base with 17,000 ㎡building area and more than 30,000 tons raw material processing capability.

Equipped with state of the art efficient-raising and energy-saving facilities, for extraction facilities, there are dynamic counter-current extraction equipment and vertical extraction tanks, which enables SanLengBio to transfer flexibly in different processing patterns.

Aiming at individual active ingre dient purification and separation, there is a full set of high-efficiency refining system.

SanLengBio start with production of Andrographis Paniculata Extract and St. John’ s Wort Extract in ZiYuan Pharmaceutical Company.

Lingchuan manufacturing base was built and passed China’s Food and Drug China’s Food and Drug Administration GMP audit.

Suqiao manufacturing base starts operation and focuses on producing Monk Fruit Extract and Citrus Fruit Extract etc.

New 3,000㎡ modern cold storage facility has been officially commissioned.

Officially take over monk fruit demonstration base from local government, with a total investment of over $5.5 million dollars.

Our phaseⅡwastewater treatment station signifies a transformative leap in environmental sustainability, the sewage treatment capacity has increased by 500% .

NATCO joint venture was set up in the United States to further expand international business.

VISIT US: www.natcohealthyliving.com

Make innovation on the production technology of 98% ursolic acid.

The construction of the second phase of the Suqiao manufacturing base began.

Purchase a new production line to increase extraction capacity.Our production capacity will be significantly increased after the facility upgrading.

In 2025, The Phase ll project of the Sugiao base has already been initiated and run.Along with 2 additional new high efficiency dynamic counter-current extraction lines.Every day over 200 tons of monk fruit can be put into production.

You are welcome to contact us.please fill in your needs in the form below,we will reply to you within 12 hours.